Painting, decorating and home improvement tips blog

How to fix squeaky floorboards

Posted by Adrian

September 23rd, 2019

How to fix squeaky and creaking floorboards

You know how it is, you creep home late at night and head up to bed trying not to wake the family, then squeak the floorboards make a noise like the floor is falling through and wakes the family, not a good scenario but one fairly common I would guess.

If you suffer from squeaky and creaking floorboards it can not only wake the family as I jokingly mentioned above it can just be annoying. Well thankfully it isn’t too much of a problem to fix them for any handyman or DIY enthusiast.

What causes squeaky floorboards

Squeaky floorboards are caused mainly by badly fitting boards. If the boards are taken up to run electrical cables or pipework and are not put back properly, or the boards nailed back using the old nails in the old nail holes which means the nails don’t have a tight fit on the board and allow for them to move and squeak. Sometimes the end of the boards are not sitting on a joist and can move rubbing against the floorboards next to it.

Another reason for squeaky floorboards is simply that the boards have dried out and the nails are no longer holding the board down tight enough or the boards have moved and are rubbing together, whatever the reason you should be able to fix the problem.

How to fix squeaky floorboards

The first thing to do is to remove the floor covering, or part of it if you can’t fully clear the room. Once the floor covering has been removed you need to tread the boards, walk around and identify the squeaks and creaks and mark the boards where the noise is with a pencil. Do this over the entire floor.

Now go back and look at each mark you have made and identify what the problem is, for just boards that are rubbing together, you can either remove a board and plane a little off the edge, or try adding some talcum powder or chalk dust between the two rubbing boards to help movement between the two boards.

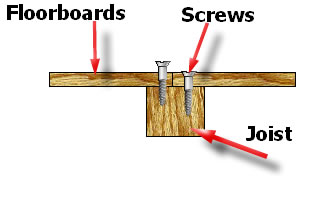

If the boards seem to be moving around the nails at the end of the boards, you need to screw these down. Don’t just put a screw in though as you may go through an electrical cable or a pipe, you may have to lift the board to see what is underneath first. Remove the nails and drill pilot holes next too the old nail holes so not to split the wood and then put a screw in making sure it pulls the board down tight.

If the board is split at the end, you may have to replace that board, or you may be able to lift it and turn it round so the other end is under the skirting board.

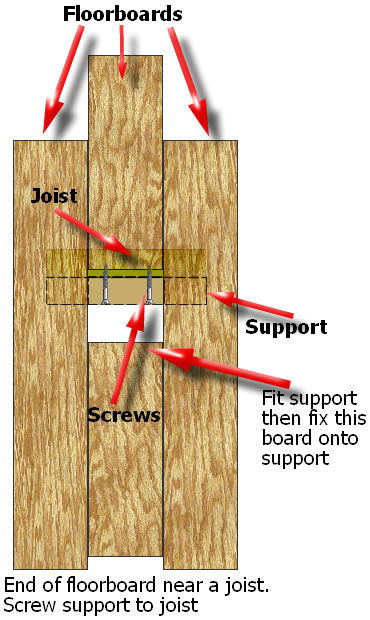

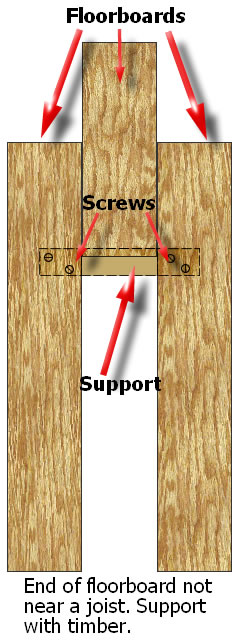

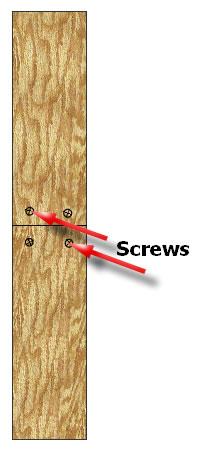

If the end of the board isn’t supported on a joist you will have to lift the board and put in a support. This can be done by lifting the unsupported board and fitting a length of 2×1 (50mm x 25mm) under the boards, ideally fixing it to a joist with screws. If a joist isn’t near, screw through the floorboards under either side of the unsupported one fixing the support to the underside of the boards, then re-fix the previously unsupported board and screw this board into the timber support you have fitted.

Do I need a new floor

Depending on how the floorboards have been lifted and cut will depend on if you need to replace boards or not, as mentioned above you may be able to lift a board and turn it around so the damaged end goes under the skirting, or even under furniture that doesn’t move. On the whole squeaky and creaking floorboards can be rectified.

How to lift floorboards

To lift floorboards you can use a club hammer and a wide bladed chisel such as a cold chisel or by using a crowbar. Prise the board up from one side then the other, be careful not to split the board, once you have the board slightly lifted up lay a piece of timber underneath to hold the end up and continue working along the board and moving the timber support as you go. If the floorboards are tongue and groove, you will need to cut the tongue off first in order not to damage the grove on the board next to it.

Safety First

Always remember to check under the floorboards for pipework and electrical cables before nailing or screwing down the floorboards, this will avoid driving a nail or screw through them. It is always a good idea to mark on the floorboards where the cables and pipes run under the floor, you can do this by using a pencil or better still a permanent marker pen. By marking the floor you will know where the cables and pipes run if you remove the floor covering or wish to run new pipework or cables in the future.

Tags: Cables, Chisel, Club Hammer, Creaking, DIY, Electrical, Floorboards, Flooring, Handyman, Nails, Pipes, Pipework, Plumbing, Squeaking, Woodwork

Posted in Home Improvements | No Comments »

Painting pipes and Pipework

Posted by Adrian

January 31st, 2017

Painting Pipes and pipework

From time to time we have to paint pipes or pipework, this can be inside or outside a property. It could be plastic PVCu drainage pipes from kitchens or bathrooms, or maybe copper water pipes for heating etc.

What ever the situation un-painted pipes can look unsightly, pipes look better painted. They maybe in a different colour, sometimes a different finish such as gloss or satinwood.

To get a good professional finish you don’t want to get paint from the pipes onto the surrounding area, such as walls. A good trick is to put cardboard of a sheet of paper or old wallpaper behind the pipes to protect the area behind getting splashed or the brush touching the wall as you try to get the back part of the pipes, once done you will have beautifully painted pipes and no paint on the walls behind.

This tip works for all types of pipework, interior and exterior.

How to paint pipes and paintwork

To paint new copper pipes you need to ensure they are free from any plumbing flux and grease, so a wipe over with soapy water, methylated spirits or white spirit should remove this. With the pipes clean you can prime the pipes and then topcoat. I prefer satinwood but you can use gloss or emulsion. Oil based paints can yellow on hot water or heating pipes due to the heat.

To paint previously painted copper pipes, give them a quick wipe over to remove any dust etc, gently rub down to give a key, prime / undercoat and them topcoat with your preferred paint.

To paint plastic PVCu pipes, such as soil pipes, drainage pipes etc, ensure they are free from dirt and debris, including any plumbing grease etc. Give them a rub down with a fine grit sandpaper to give it a key, then prime, and paint with topcoat of choice.

Tags: Bathroom, Copper, Downpipe, heating, Kitchen, Painting, Pipes, Pipework, Plumbing, UPVC

Posted in Decorating Tips | No Comments »