Painting, decorating and home improvement tips blog

How to secure outbuildings and sheds

Posted by Adrian

August 31st, 2020

How to secure outbuildings and sheds

We all struggle for storage spaces and often fill our sheds, garages, summerhouses and outbuildings with ‘stuff’, now whether we need it or not or simply store it until we go to the local dump with it the problem is all the same.

Sometimes we may have a man cave where we go and organise our tools and tinker on the latest product, or maybe we have turned our shed into our office? Whatever we use the buildings for we need to make sure they are secure as they can often be easy pickings for thieves.

Keeping it secure

The simplest way and cheapest way is to fit a padlock onto the door using a hasp and staple. However, you can go further and install alarms and CCTV but this choice comes down to what you keep stored away.

The very least should be a lock of some kind, this will deter the opportunist thief. Adding locks is far cheaper than replacing stolen belongings such as bikes, lawn mowers etc. Once you have a lock fitted, always lock up when you are finished.

If your outbuilding has windows you could put bars over the window to stop easy access through the window, if the windows are lockable, lock them.

Lights, CCTV, Alarm

If you have more valuable stuff stored away such as bikes or your outbuilding is a home office you may wish to consider adding a little more security than just a padlock. An exterior light fitted with a PIR (passive infrared sensor) that comes on when movement is detected is a good idea and could scare off would be thieves.

If you want to keep an eye on what is going on you can install a simple CCTV system, these have come down in price in recent years and will allow you to see what is going on and who maybe lurking around. There are many systems to choose from, many are self install and can be connected to a PC or TV for viewing.

An alarm could also be fitted, these can be self install and don’t have to cost a lot of money for a basic system. A simple PIR (passive infrared sensor) and one or two door / window magnetic sensors should come in under £100.00.

Securing other items

Some people may have extension ladders that do not fit into a shed, garage or outbuilding and simply leave these lying on the garage roof or just in the back garden, well these can be used to gain access to yours on someone else’s property, securing these is simple and cheap, ladder clamps that allow ladders to be securely hung on a wall, or a simple heavy duty chain and padlock secured to a permanent fixture will prevent them being used.

Other items such as screwdrivers, hammers etc. shouldn’t be left around in the garden for example as these can aid a burglars access to a property or outbuilding.

Keeping keys safe

If you have several people needing access to outbuildings, garages, or even just to your house but you don’t want to give keys to lots of people. The ideal solution is a key safe that is secured to a wall, the keys safe, or box, has a changeable combination. So all you need do is to give the combination code to people, and you can change the code at any time. These boxes range in size and price, but it is worth paying for a good one, even one that is police approved.

In conclusion

We all have to store things and most often this is done in outbuildings, simple steps such as those listed above could prevent items being taken or use to gain access to a property.

They don’t have to cost a lot and it is up to you how far you want to go, be it a simple padlock or more secure with locks, security lights, CCTV and alarms, this will mainly come down to the area you live in and the value of items stored.

Tags: Alarm, Burglar Alarm, CCTV, Clamp, extension ladder, garage, Hasp, ladder, Lights, Outbuilding, Padlock, PIR, shed, Staple, Summerhouse

Posted in Home Improvements | No Comments »

Boxing in pipework

Posted by Adrian

July 31st, 2020

Boxing in pipework

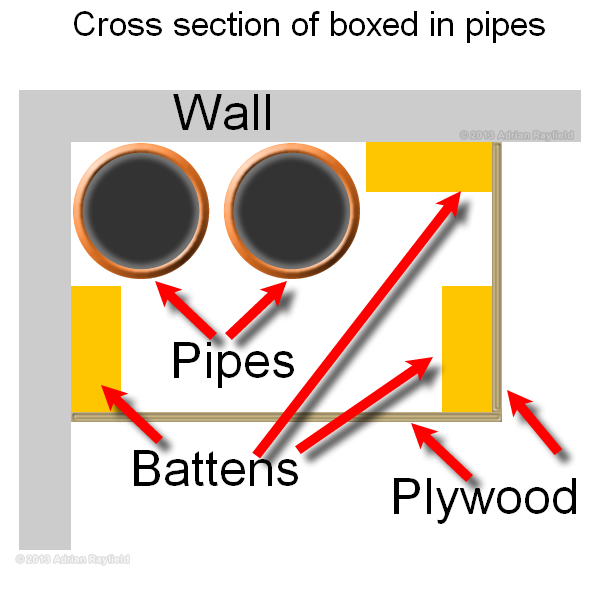

Pipes such as heating pipes or waste pipes can look ugly and can be a dust trap, they can be hard to clean and even paint around. The ideal solution is to box pipework in, once they are boxed in, the box can be decorated the same as the surrounding area, such as tiled or painted.

Typically to box in pipework you use timber battens and plywood or MDF, the battens are normally 2×1 inches (50×25 mm) or 2×2 (50×50 mm). The plywood or MDF can be 6 or 9 mm. All of the materials used will depend on the circumstances you plan to box the pipes in. You may even wish to use plasterboard and plaster the box.

Tools required for this job

- Battens (2×1 or 2×2) (50×25 mm or 50×50 mm)

- Drill

- Drill bits

- Screw or panel pins

- Spirit level

- Screwdriver / drill with screwdriver bit

- Hammer

- Plywood, MDF, Plasterboard

- A pencil

- Tape measure

How to box in pipes

Take the battens and hold them against the wall, use a spirit level to ensure they are upright and level, next drill holes through the wood into the wall, use rawl plugs and screws to fit the batten to the wall ensuring they are level.

Once the two wall battens are fixed you can cut the plywood to the correct size, fix a batten on the outside corner of one of the pieces of plywood, this will allow you to screw the other length of plywood to it giving the external corner a good strong fixing.

Decorating the box

Once the boxing in is done you can decorate the box, if you are painting the box, fill the screw holes and rub them down then apply the appropriate paint to match the surrounding area, you may have to prime the box first to seal the plywood. If you are tiling the boxing in, cut and fix the tiles to match in with to other tiles. You can add skirting boards to horizontal boxing in to match the room, and coving to vertical boxing in to make the box become part of the room and once decorated should like it has always been there.

Horizontal and vertical pipes

The same method for boxing in applies if you are boxing in horizontal or vertical pipes.

You can box in heating pipes, hot and cold water pipes, soil pipes and waste pipes to tidy them up and make them look part of the room.

Tags: Boxed in, Cold Pipes, Decorating, Heating Pipes, Hot Pipes, Painting, Pipes, Soil pipes, Tiling, Waste Pipe

Posted in Decorating Tips, Home Improvements | No Comments »

How to build a step

Posted by Adrian

June 30th, 2020

How to build a step

On a recent job I was asked if I could repair a step to a back door, the step was already built out of Celcon blocks and rendered over. The rendering had broken off and become loose over time. I was asked to re-render the step, which I did. I have included some photos of the finished job below.

Building a step

Before you build your outside step you need to work out the height, width and depth of your step, you also need to decide on the materials used to build it, such as concrete, bricks, blocks, block paving blocks, are you going to top it off with slabs?

Once this has all been decided you can start building your step. If you are going to use bricks, lay the edge bricks out to make sure you are happy with the size, you can then fix these down with mortar. Once these are set you can fill in using sand and cement, concrete or hardcore. You can then fix slabs on the top.

If you are going to use concrete only you are going to need to build a form (this is a temporary mold) use timber such as skirting boards to build the shape and size of the step you require, once you have done this you can mix and pour the concrete into the form, tamp it down to ensure all areas are filled and any air bubbles come to the top. You are going to want to have a textured finish the the top of the step to avoid it becoming slippery when wet of with snow and ice on it. The best way to do this is once the concrete is at the top of the form and levelled off, take a piece of wood wider than the step and tamp down across the form, this should leave ridges in the top of the concrete so when it dries you are left with a non-slip surface.

Once the concrete has set you can remove the form leaving you with a concrete step.

With the step I repaired the blocks were already in place, all I had to do was re-render the step, I did this by removing the loose render, cleaning the exposed bricks and sealing with a PVA sealer to aid adhesion. I then mixed up my render and rendered the step, I did this without a form so I could render the top and sides in finish the surface. Once I had got the basic shape, and ensured the top of the step sloped away from the house I left it to dry for a few hours, I then returned to see if it had set enough to ‘work’, which it had, at this point I used a rendering float to rub over the step, this showed up and low spots I needed to fill in. Once this was done I rubbed over with the rendering float to remove the sharp square edges and to leave a non-slip textured step and sides. I then painted the edges of the step to match the plinth, which also had a repair done to it.

To finish off I painted the plinth and the edge of the step in black bitumen paint.

Finished step

Below is the step that I repaired and painted.

Tags: Building a step, Concrete Step, Doorstep, Render, Step, Step Repair

Posted in Home Improvements | No Comments »